Elimination of Hot Tears through Optimized Cooling Control

They are cost-intensive and, in extreme cases, jeopardize the start of production: casting defects that can lead to functional failures. Ever shorter development times increase the risk of defects. The pressure on virtual component and process development to minimize the risk in advance is therefore all the greater.

While the reliable prediction of shrinkage porosity is now part of the standard repertoire of foundries in the automotive industry, the reliable prediction of individual hot tears is still in its infancy. Al-though it is possible to predict critical areas, the number of predicted defects often exceeds the number of hot tears that actually occur. Therefore, the prevention of hot tears must currently still takes place in the prototype phase as a part of process development.

Martinrea Honsel, a global supplier of light metal components and long-time user of MAGMASOFT ®, clearly demonstrated how simulation can be used to quickly minimize the occurrence of hot tears in the process development of a crankcase.

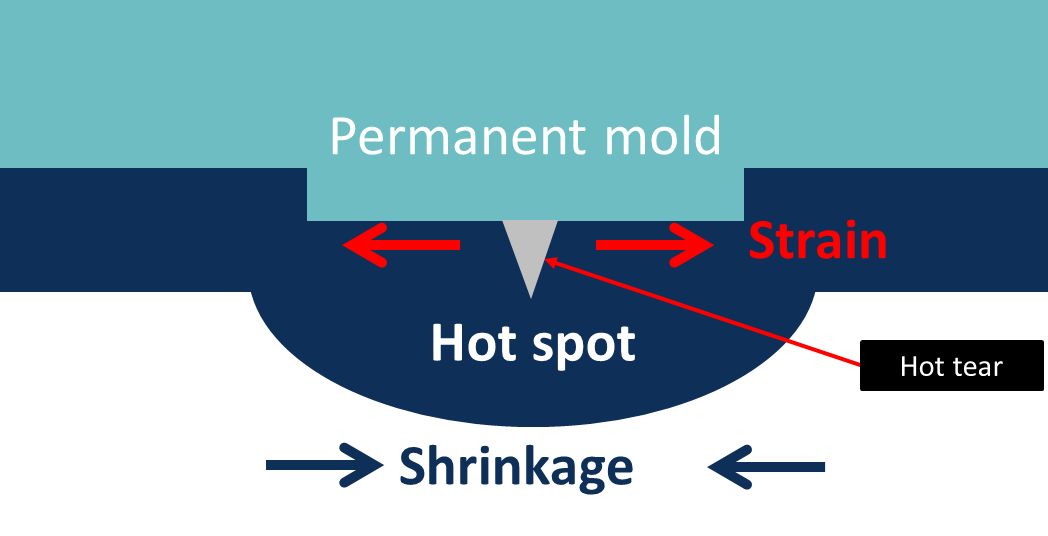

During solidification, stresses occur in a casting due to uneven cooling rates. If these reach the material’s tensile strength before the solidus temperature is reached, so-called hot tears occur (Fig. 1). Hot tearing is encouraged by large local differences in wall thickness and by shrinkage hindrance due to rigid cores or the die.

The solidification behavior of the alloy is of particular importance for hot tear formation. In general, the microstructure shows a very brittle behavior when just above the solidus temperature. Even a small mechanical strain caused by hindered thermal contraction can lead to hot tearing. If an alloy has a narrow solidification interval, the hot tear can often be “healed” by being fed by melt flow. However, if an alloy has a wide solidification interval, this feeding flow is hindered at an early stage due to the already dense dendritic network. A crack which has formed can no longer be “healed” by melt flow, resulting in the formation of a hot tear. The A226 alloy most commonly used for crankcases has such a wide solidification interval and is known for its tendency for hot tearing.

Early Detection of Possible Defects

For analyzing critical areas, the stress module MAGMAstress calculates a hot tear result at any time during solidification and cooling. The evaluation of the local strain rate – from the point in time where no further feeding through the dendritic structure is possible – is an important parameter for the calculation of the hot tear criterion. It also takes into account that the hot tearing tendency increases with the solidification time.

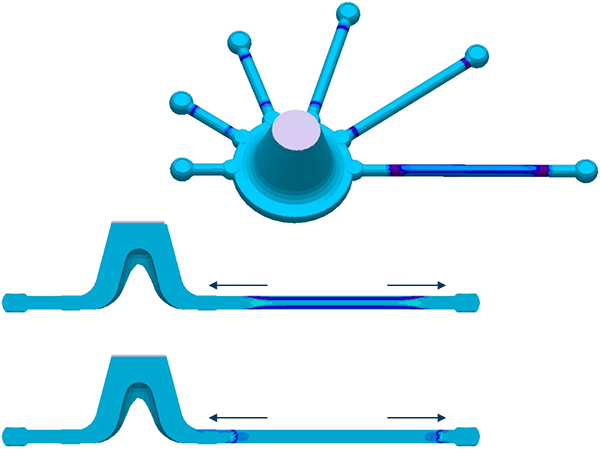

The hot tear criterion can be adjusted and validated with the help of test castings. For this purpose, test bars of different lengths whose shrinkage is hindered during solidification by thickened sections were cast, (Fig. 2). This results in the highest strains at the contact points between thick and thin sections with the magnitude of the strain increasing with the length of the bars. The shortest bar thus displays the lowest hot tear tendency, whereas the longest bar has the highest hot tear tendency.

The tests confirmed the results of the simulation. The shortest bar did not show cracks in any of the tests, whereas the longest bar tore in each of the tests. In comparison with the simulation, the tests bars only tear at one location because the first crack leads to an immediate stress relief.

With the hot tear criterion, critical areas can be identified early on. The calculation is based on a stress calculation that considers both the casting and the die. This makes the calculation very time-consuming, even if significant computing power is available. To reduce the calculation time for an optimization of the casting layout, in this case a modified coo-ling for an existing casting, Martinrea Honsel has developed a methodology that also allows the qualitative risk assessment for areas prone to hot tearing using a greatly simplified model . The transferability of the results of this optimization is then verified using the conventional hot tear prediction (which is based on a full stress calculation).

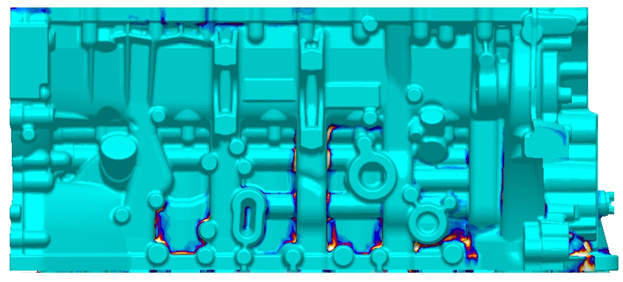

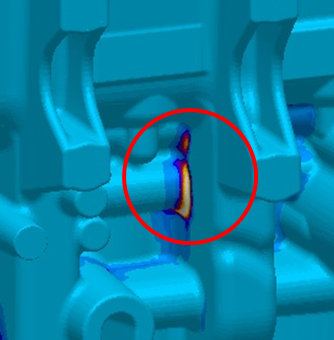

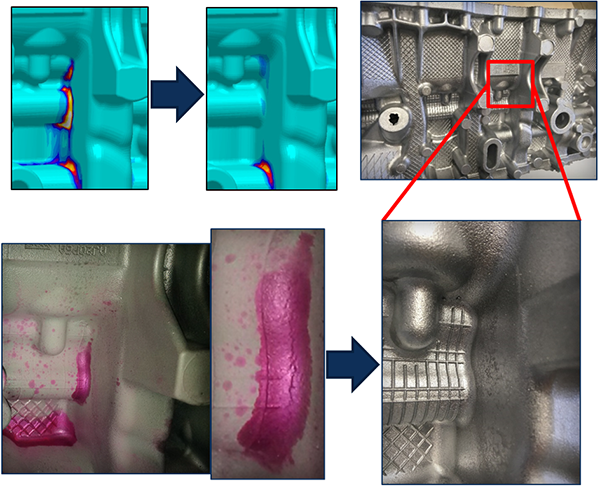

The starting point for optimization in this case was a crankcase in which hot tearing occurred reproducibly during prototype production as a low pressure die casting. The position of the hot tear can be reproduced using a MAGMASOFT® stress simulation (Fig. 3).

The simplified hot tear criterion (SHC) defined by Martinrea Honsel evaluates the differences in the solidification time in the region where the hot tear occurs and the solidification time of the area influenced by cooling. The criterion can be generated and evaluated using evaluation areas in MAGMASOFT® with a so-called “user-result”.

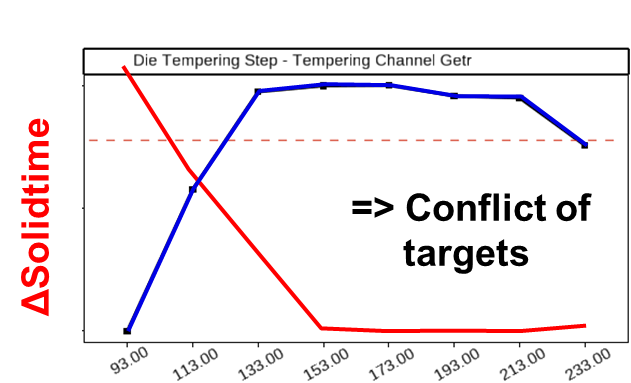

As a variable for the systematic optimization of the process conditions, the time at which cooling is activated was chosen. The optimization objectives were to minimize the SHC as well as the porosity.

The main effects diagram from the optimization (Fig. 4) reveals a significant decrease of the SHC up to a cooling activation time of 153 seconds. For a later cooling start time, no significant improvement occurs. In contrast, the risk of porosity in the defined region grows, as expected, with increasing cooling start times. From a start time of 133 seconds and longer, there is no further significant increase. There is therefore a classical “conflict of objectives” between the two objectives for optimizing the hot tear tendency and feeding, respectively. Obviously, the only possible time window for an optimal solution is between 93 and 133 seconds.

Checking the Results

To check the optimization results, a start time was selected approximately in the middle of the optimum window and a conventional stress simulation was performed. The porosity result in the selected region is not yet critical, but the “real” Hot Tear criterion result already shows a significant reduction compared to the original situation. The casting trials, which were carried out with the help of the optimized control of the timing of the cooling, show neither hot tearing nor porosity in the critical area.

This example clearly shows how the efficient combination of stress-based hot tear prediction with a simplified model for efficiently analyzing different variants can identify areas in the casting at risk as well identify those process variables which have a significant influence. In this way, quality assurance measures for the casting can be quickly derived (Fig. 5).

Courtesy of Martinrea Honsel

Martinrea Honsel

Continuity and innovative strength characterize the history of Martinrea Honsel, which the company founder Fritz Honsel first wrote over 100 years ago. Over the years, the company has repeatedly succeeded in translating customer wishes and requirements into innovative processes and products. Today, Martinrea Honsel is a recognized development and series production partner of the automotive industry. At its facilities in Germany, Spain, Brazil, Mexico and China, the group manufactures aluminum components for engines, transmissions, suspensions and chassis of passenger cars and commercial vehicles, as well as for mechanical engineering and other applications.